Poisson's ratio

due to tension, and contracted in the y and z directions by

due to tension, and contracted in the y and z directions by  .

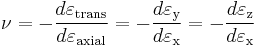

.Poisson's ratio (ν), named after Siméon Poisson, is the ratio, when a sample object is stretched, of the contraction or transverse strain (perpendicular to the applied load), to the extension or axial strain (in the direction of the applied load).

When a material is compressed in one direction, it usually tends to expand in the other two directions perpendicular to the direction of compression. This phenomenon is called the Poisson effect. Poisson's ratio ν (nu) is a measure of the Poisson effect. The Poisson ratio is the ratio of the fraction (or percent) of expansion divided by the fraction (or percent) of compression, for small values of these changes.

Conversely, if the material is stretched rather than compressed, it usually tends to contract in the directions transverse to the direction of stretching. Again, the Poisson ratio will be the ratio of relative contraction to relative stretching, and will have the same value as above. In certain rare cases, a material will actually shrink in the transverse direction when compressed (or expand when stretched) which will yield a negative value of the Poisson ratio.

The Poisson's ratio of a stable, isotropic, linear elastic material cannot be less than −1.0 nor greater than 0.5 due to the requirement that the elastic modulus, the shear modulus and bulk modulus have positive values [1]. Most materials have Poisson's ratio values ranging between 0.0 and 0.5. A perfectly incompressible material deformed elastically at small strains would have a Poisson's ratio of exactly 0.5. Most steels and rigid polymers when used within their design limits (before yield) exhibit values of about 0.3, increasing to 0.5 for post-yield deformation (which occurs largely at constant volume.) Rubber has a Poisson ratio of nearly 0.5. Cork's Poisson ratio is close to 0: showing very little lateral expansion when compressed. Some materials, mostly polymer foams, have a negative Poisson's ratio; if these auxetic materials are stretched in one direction, they become thicker in perpendicular directions. Anisotropic materials can have Poisson ratios above 0.5 in some directions.

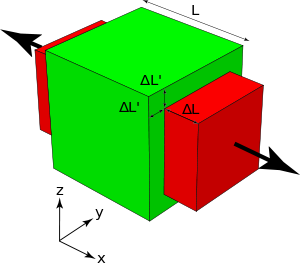

Assuming that the material is stretched or compressed along the axial direction (the x axis in the diagram):

where

is the resulting Poisson's ratio,

is the resulting Poisson's ratio, is transverse strain (negative for axial tension (stretching), positive for axial compression)

is transverse strain (negative for axial tension (stretching), positive for axial compression) is axial strain (positive for axial tension, negative for axial compression).

is axial strain (positive for axial tension, negative for axial compression).

Contents |

Cause of Poisson’s effect

On the molecular level, Poisson’s effect is caused by slight movements between molecules and the stretching of molecular bonds within the material lattice to accommodate the stress. When the bonds elongate in the direction of load , they shorten in the other directions. This behavior multiplied millions of times throughout the material lattice is what drives the phenomenon.

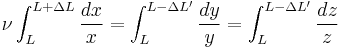

Length change

For a cube stretched in the x-direction (see figure 1) with a length increase of  in the x direction, and a length decrease of

in the x direction, and a length decrease of  in the y and z directions, the infinitesimal diagonal strains are given by:

in the y and z directions, the infinitesimal diagonal strains are given by:

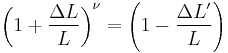

Integrating the definition of Poisson's ratio:

Solving and exponentiating, the relationship between  and

and  is found to be:

is found to be:

For very small values of  and

and  , the first-order approximation yields:

, the first-order approximation yields:

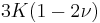

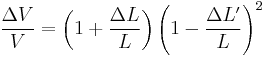

Volumetric change

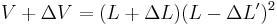

The relative change of volume ΔV/V due to the stretch of the material can now be calculated. Using  and

and  :

:

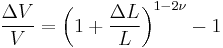

Using the above derived relationship between  and

and  :

:

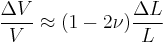

and for very small values of  and

and  , the first-order approximation yields:

, the first-order approximation yields:

Width change

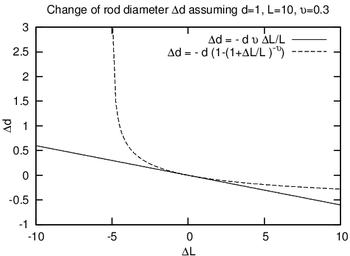

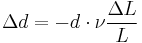

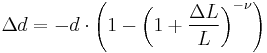

If a rod with diameter (or width, or thickness) d and length L is subject to tension so that its length will change by ΔL then its diameter d will change by:

The above formula is true only in the case of small deformations; if deformations are large then the following (more precise) formula can be used:

where

is original diameter

is original diameter is rod diameter change

is rod diameter change is Poisson's ratio

is Poisson's ratio is original length, before stretch

is original length, before stretch is the change of length.

is the change of length.

The value is negative because the diameter will decrease with increasing length.

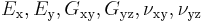

Isotropic materials

For a linear isotropic material subjected only to compressive (i.e. normal) forces, the deformation of a material in the direction of one axis will produce a deformation of the material along the other axes in three dimensions. Thus it is possible to generalize Hooke's Law (for compressive forces) into three dimensions:

or

where

,

,  and

and  are strain in the direction of

are strain in the direction of  ,

,  and

and  axis

axis ,

,  and

and  are stress in the direction of

are stress in the direction of  ,

,  and

and  axis

axis is Young's modulus (the same in all directions:

is Young's modulus (the same in all directions:  ,

,  and

and  for isotropic materials)

for isotropic materials) is Poisson's ratio (the same in all directions:

is Poisson's ratio (the same in all directions:  ,

,  and

and  for isotropic materials)

for isotropic materials)

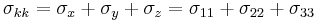

These equations will hold in the general case which includes shear forces as well as compressive forces, and the full generalization of Hooke's law is given by:

where  is the Kronecker delta and

is the Kronecker delta and

Orthotropic materials

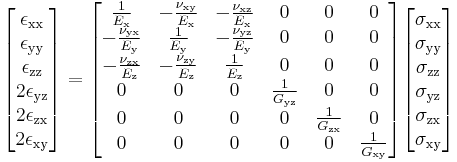

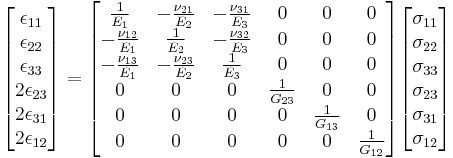

For orthotropic materials such as wood, Hooke's law can be expressed in matrix form as[2]

where

is the Young's modulus along axis

is the Young's modulus along axis

is the shear modulus in direction

is the shear modulus in direction  on the plane whose normal is in direction

on the plane whose normal is in direction

is the Poisson's ratio that corresponds to a contraction in direction

is the Poisson's ratio that corresponds to a contraction in direction  when an extension is applied in direction

when an extension is applied in direction  .

.

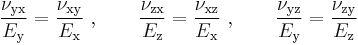

The Poisson's ratio of an orthotropic material is different in each direction (x, y and z). However, the symmetry of the stress and strain tensors implies that not all the six Poisson's ratios in the equation are independent. There are only nine independent material properties; three elastic moduli, three shear moduli, and three Poisson's ratios. The remaining three Poisson's ratios can be obtained from the relations

From the above relations we can see that if  then

then  . The larger Poisson's ratio (in this case

. The larger Poisson's ratio (in this case  ) is called the major Poisson's ratio while the smaller one (in this case

) is called the major Poisson's ratio while the smaller one (in this case  ) is called the minor Poisson's ratio. We can find similar relations between the other Poisson's ratios.

) is called the minor Poisson's ratio. We can find similar relations between the other Poisson's ratios.

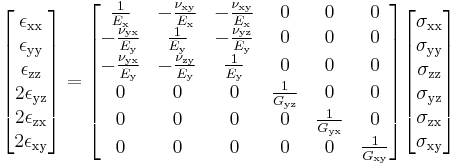

The above stress-strain relation is also often written in the equivalent (transposed) form[3]

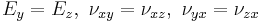

Transversely isotropic materials

Transversely isotropic materials have a plane of symmetry in which the elastic properties are isotropic. If we assume that this plane of symmetry is  , then Hookes's law takes the form[4]

, then Hookes's law takes the form[4]

where we have used the plane of symmetry  to reduce the number of constants, i.e.,

to reduce the number of constants, i.e.,  .

.

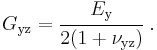

The symmetry of the stress and strain tensors implies that

This leaves us with six independent constants  . However, transverse isotropy gives rise to a further constraint bewtween

. However, transverse isotropy gives rise to a further constraint bewtween  and

and  which is

which is

Therefore, there are five independent elastic material properties two of which are Poisson's ratios. For the assumed plane of symmetry, the larger of  and

and  is the major Poisson's ratio. The other major and minor Poisson's ratios are equal.

is the major Poisson's ratio. The other major and minor Poisson's ratios are equal.

Poisson's ratio values for different materials

| material | poisson's ratio |

|---|---|

| rubber | ~ 0.50 |

| gold | 0.42 |

| saturated clay | 0.40-0.50 |

| magnesium | 0.35 |

| titanium | 0.34 |

| copper | 0.33 |

| aluminium-alloy | 0.33 |

| clay | 0.30-0.45 |

| stainless steel | 0.30-0.31 |

| steel | 0.27-0.30 |

| cast iron | 0.21-0.26 |

| sand | 0.20-0.45 |

| concrete | 0.20 |

| glass | 0.18-0.3 |

| foam | 0.10 to 0.40 |

| cork | ~ 0.00 |

| auxetics | negative |

| material | plane of symmetry |  |

|

|

|

|

|

|---|---|---|---|---|---|---|---|

| Nomex honeycomb core |  , ,  =ribbon direction =ribbon direction |

0.49 | 0.69 | 0.01 | 2.75 | 3.88 | 0.01 |

| glass fiber-epoxy resin |  |

0.29 | 0.29 | 0.32 | 0.06 | 0.06 | 0.32 |

Negative Poisson's ratio materials

Some materials known as auxetic materials display a negative Poisson’s ratio. When subjected to positive strain in a longitudinal axis, the transverse strain in the material will actually be positive (i.e. it would increase the cross sectional area). For these materials, it is usually due to uniquely oriented, hinged molecular bonds. In order for these bonds to stretch in the longitudinal direction, the hinges must ‘open’ in the transverse direction, effectively exhibiting a positive strain.[6]

Applications of Poisson's effect

One area in which Poisson's effect has a considerable influence is in pressurized pipe flow. When the air or liquid inside a pipe is highly pressurized it exerts a uniform force on the inside of the pipe, resulting in a radial stress within the pipe material. Due to Poisson's effect, this radial stress will cause the pipe to slightly increase in diameter and decrease in length. The decrease in length, in particular, can have a noticeable effect upon the pipe joints, as the effect will accumulate for each section of pipe joined in series. A restrained joint may be pulled apart or otherwise prone to failure.[7]

Another area of application for Poisson's effect is in the realm of structural geology. Rocks, like most materials, are subject to Poisson's effect while under stress. In a geological timescale, excessive erosion or sedimentation of Earth's crust can either create or remove large vertical stresses upon the underlying rock. This rock will expand or contract in the vertical direction as a direct result of the applied stress, and it will also deform in the horizontal direction as a result of Poisson's effect. This change in strain in the horizontal direction can affect or form joints and dormant stresses in the rock.[8].

The use of cork as a stopper for wine bottles is the result of the fact that cork has a Poisson ratio of practically zero. This means that, as the cork is inserted into the bottle, the upper part which is not yet inserted will not expand as the lower part is compressed. The force needed to insert a cork into a bottle arises only from the compression of the cork and the friction between the cork and the bottle. If the stopper were made of rubber, for example, (with a Poisson ratio of about 1/2), there would be a relatively large additional force required to overcome the expansion of the upper part of the rubber stopper.

See also

- 3-D elasticity

- Hooke's Law

- Impulse excitation technique

- Orthotropic material

- Coefficient of thermal expansion

References

- ↑ H. GERCEK; “Poisson's ratio values for rocks”; International Journal of Rock Mechanics and Mining Sciences; Elsevier; January 2007; 44 (1): pp. 1–13.

- ↑ Boresi, A. P, Schmidt, R. J. and Sidebottom, O. M., 1993, Advanced Mechanics of Materials, Wiley.

- ↑ Lekhnitskii, SG., (1963), Theory of elasticity of an anisotropic elastic body, Holden-Day Inc.

- ↑ Tan, S. C., 1994, Stress Concentrations in Laminated Composites, Technomic Publishing Company, Lancaster, PA.

- ↑ Poisson's ratio calculation of glasses

- ↑ Negative Poisson's ratio

- ↑ http://www.cpchem.com/hb/getdocanon.asp?doc=135&lib=CPC-Portal

- ↑ http://www.geosc.psu.edu/~engelder/geosc465/lect18.rtf

External links

- Meaning of Poisson's ratio

- Negative Poisson's ratio materials

- More on negative Poisson's ratio materials (auxetic)

|

|||||

| Conversion formulas | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Homogeneous isotropic linear elastic materials have their elastic properties uniquely determined by any two moduli among these, thus given any two, any other of the elastic moduli can be calculated according to these formulas. | ||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

![\varepsilon_x = \frac {1}{E} \left [ \sigma_x - \nu \left ( \sigma_y + \sigma_z \right ) \right ]](/I/f96cf49b267ede9e47bbfb3b7249873f.png)

![\varepsilon_y = \frac {1}{E} \left [ \sigma_y - \nu \left ( \sigma_x + \sigma_z \right ) \right ]](/I/1677af686fe5f6b3ee69c910b84445ee.png)

![\varepsilon_z = \frac {1}{E} \left [ \sigma_z - \nu \left ( \sigma_x + \sigma_y \right ) \right ]](/I/2fc0dc49396a59c7df5f108a78d82d96.png)

![\varepsilon_i = \frac {1}{E} \left [ \sigma_i(1+\nu) - \nu \left ( \sigma_x + \sigma_y+\sigma_z \right ) \right ]](/I/cc4142e21b2f2d4e80b5fa36c0c1b21c.png)

![\varepsilon_{ij} = \frac {1}{E} \left [ \sigma_{ij}(1+\nu) - \nu \delta_{ij}\sigma_{kk} \right ]](/I/aced89f2a750bf36f20e3feeeb08170c.png)

) •

) •  ) •

) •  ) • Poisson's ratio (

) • Poisson's ratio ( )

)